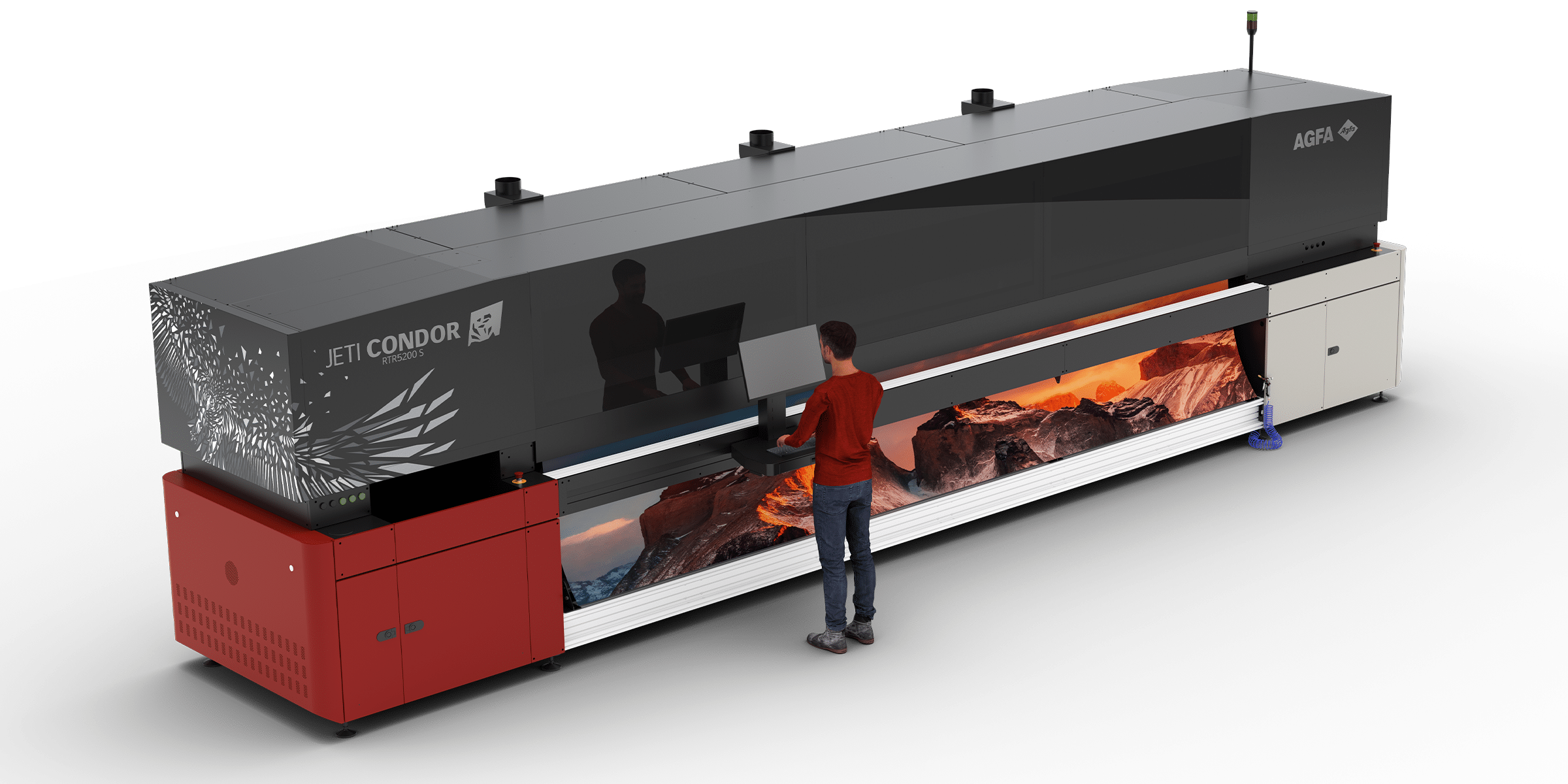

Jeti Condor RTR5200

High-productivity, high-quality 5.2 m roll-to-roll inkjet printer

With its impressive wingspan, the condor soars high above the landscape, gliding effortlessly for long distances with minimal energy. Take a bird’s eye view on your wide-format business and let the 5-meter Condor roll-to-roll printer take you under its wings and guide you to new horizons.

- Roll-to-roll

- Up to 672 m²/h – 7233 ft²/h

- Up to 528 cm – 208 in

- CMYKcm – Optional light cyan, light magenta, light black, white & clear fluid

- Automatable

- Upgradable colors

Why the Condor is the right beast for you

Boasting a maximum print width of 5,2 m and a max productivity of 672 m²/h, the Jeti Condor RTR5200 printer sets the industry standard in the roll-to-roll printer market.

- The highest image quality at the highest rated speeds – native 7 pl drop reaching resolutions up to 1200 dpi

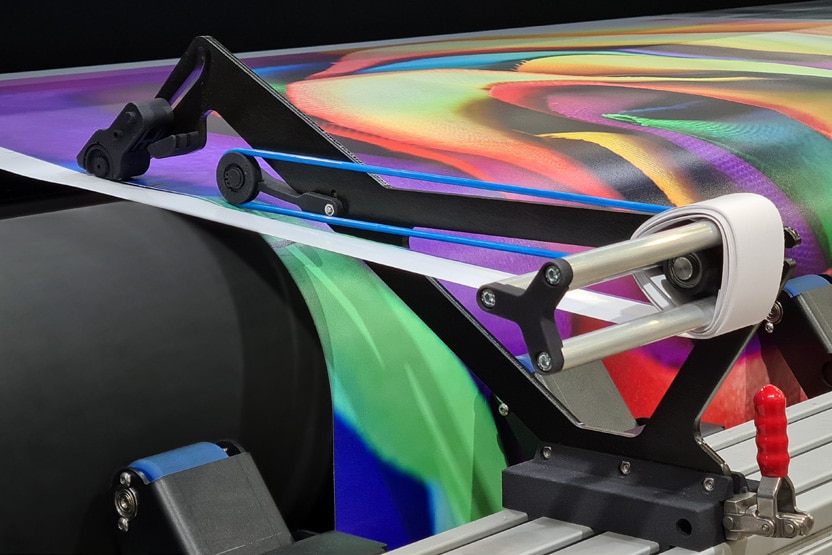

- Single roll-to-roll, free-fall, and dual/multi-roll (up to 3 rolls of 63 in)

- Quick and easy media loading to handle a wide variety of flexible substrates

- A wide array of design and application possibilities thanks to the clear fluid printing option and the superb white ink printing performance in single- and multi-layer print modes

- Continuous printing with minimal supervision – also for backlit printing – using multiple media handling solutions for large and heavy rolls

- Automated technology for printing mesh

- Complete print-to-finished graphic workflow saves time, replaces expensive finishing equipment, limits operator intervention, prevents errors and increases yield

- Low total cost of ownership (TCO) with low power consumption, low ink consumption, and optional tools that save waste, labor, floor space – and ultimately money

High-value applications

Condor RTR5200 printer models

Condor RTR5200 S

- Up to 479 m²/h

- 2 rows of colored printheads

Condor RTR5200 HS

- Up to 672 m²/h

- 3 rows of colored printheads

Color options

In addition to the standard CMYK colors, the Condor roll-to-roll printers offer optional seven-color printing, white, and clear fluid, adding a wide range of high-margin applications to your portfolio.

7-color printing

The addition of light cyan, light magenta and light black achieves smooth gradient transitions and skin tones, crisp colors, and fine details. Based on existing printhead configuration, without adding more heads.

White ink

Superb white ink printing performance enables printing on colored and transparent media and opens up a myriad of creative possibilities. Multi-layer print modes for backlit applications and blockout printing.

Clear fluid

The Anuvia 1480 clear fluid can be used for decorative applications as well as for a final protective coating. It prints inline, simultaneously with the image, saving time versus using a separate offline coating system. The clear fluid can be applied selectively or in full flood. There are gloss or matte finishes. clear fluid provides up to three years protective coating and print enhancement.

White and clear fluid together

On the Condor RTR5200 HS, you can print white and clear fluid simultaneously for even more enhanced design and application possibilities.

Tools to boost your capabilities and profits

The Condor features a unique collection of value-added options that transform them into all-in-one, multi-purpose platforms that automate processes, minimize waste, increase usability, expand your applications offering, and enhance profit.

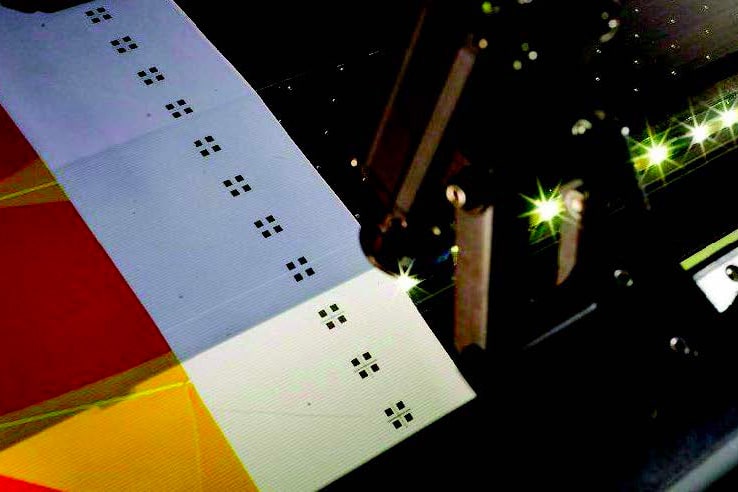

Automatic inline print quality monitoring that can identify various print imperfections and alert the operator.

Only available on the Condor RTR5200 HS

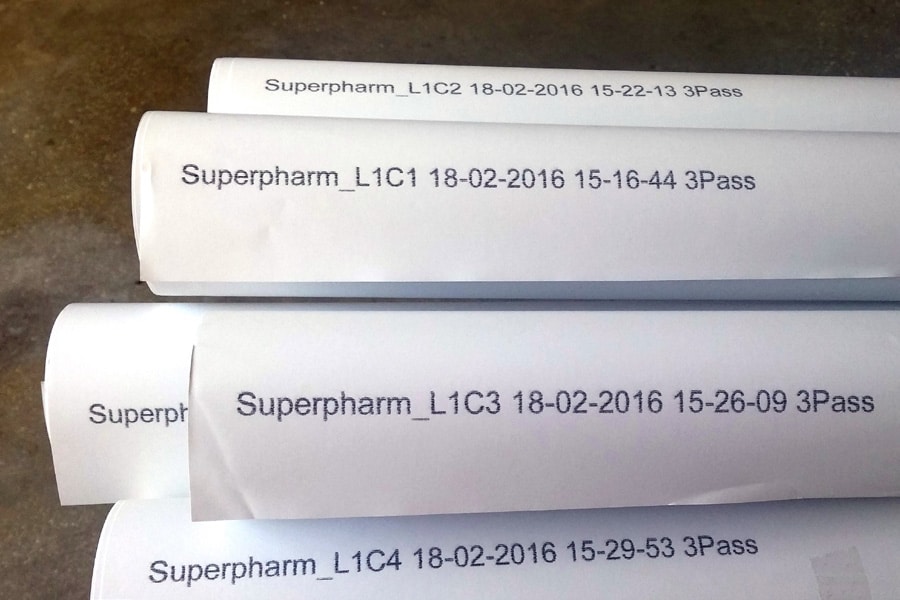

For printing customer information on the rear of the media; also available with white ink for color-backed media. Facilitates the identification of the finished job for packing, shipping and installation.

For the vertical trimming of margins or slitting media into multiple jobs, minimizing media waste and increasing the printing area. With waste collectors. Single- or double-bladed.

Cuts media on the X-axis on the fly, without slowing down printing.

An automated device that takes printed cut sheets directly from the printer, rolls them into scrolls, and tapes their edges with labels with printed job information.

Optical sensor that enables automated printing on both sides of opaque blockout media with excellent registration. Supports cutting and slitting.

Uses cameras, a LED strip and software to enable printing each side with a different print mode. Accuracy of ≤ 2 mm over 10 linear meters.

For loading heavy media rolls. Increases productivity in high-volume runs due to less make-ready. Enables continuous, unattended work.

For precise media collection of larger and heavier rolls up to 400 kg. Supports full printer width media & multi-roll.

For media with uneven or wavy edges protect the print carriage and printheads, preventing waste media.

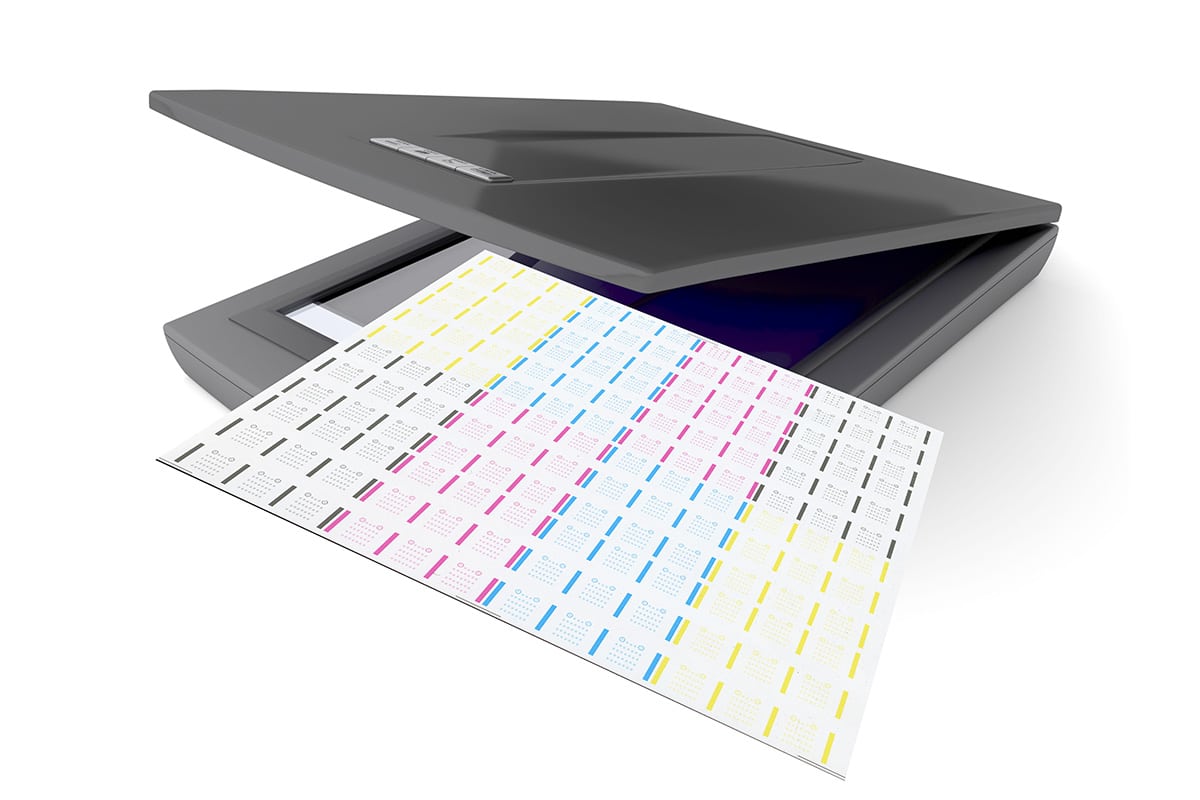

Software and a dedicated scanner enable you to self-diagnose and fix print quality issues, including calibration or missing nozzles. This will increase your uptime and extend the printhead lifespan.

Only available on the Condor RTR5200 HS

Gets the printer it to its optimal print quality state. Can be performed every few months by a skilled onsite operator.

Only available on the Condor RTR5200 HS

Powered by Asanti workflow software

Asanti ——Dedicated Sign & Display workflow software

The Jeti Condor engines are driven by Agfa’s award-winning wide-format workflow software Asanti, which controls the entire printing process from prepress to production and finishing. As such, it simplifies, optimizes and automates as many steps as possible, offering you a high-performance solution for increased productivity.

Simplify & automate

Including the latest Adobe PDF Print Engine, Asanti takes care of preflighting and job conversion to guarantee smooth, error-free job handling and consistent print quality. In addition, Asanti streamlines your print operations through automatic job layout and positioning, and automatic true-shape-nesting. The automatic collection of images allows you to gather all artwork for a specific press and specific media, and to optimally nest it on the print sheet or roll, taking copy count and bleed into account.

Asanti guarantees consistent color reproduction through the creation and use of color profiles. To do so, it deploys the patented Calibrated Print Mode (CPM) feature, which uses easy-to-set-up production templates that contain all parameters for a particular substrate and enable automatic job creation. It will only take you 15 minutes to calibrate and profile media, and then you can enjoy hassle-free printing with optimal and consistent quality!

The Asanti Production Dashboard is a browser-based reporting tool that allows you to inspect the status, ink and media consumption, and printing time of jobs.

Technical data

Jeti Condor RTR5200

Models | Jeti Condor RTR5200 S | Jeti Condor RTR5200 HS |

|---|---|---|

4C – CMYK (16 print heads)

Options:

* White & clear fluid cannot be combined | 4C – CMYK (24 print heads)

Options:

| |

Productivity | Up to 479 m²/h (5,156 ft²/h) | Up to 672 m²/h (7,233 ft²/h) |

Media & printing specifications – Roll-to-Roll

Maximum media width | 530 cm (209”) |

|---|---|

Maximum print width | 520 cm (208”) |

Maximum length | Full roll length (depends on total roll thickness, diameter and weight) |

Thickness | Maximum 30 mm |

Maximum weight | 225 kg (496 lb) 400 kg (882 lb) with motorized inflatable air shafts 2000 kg (4410 lb) with Master Roll-to-Roll unit |

Maximum roll diameter | Internal: 320 mm (12.6”) External: 480 mm (18.9”) |

Roll mounting | Pneumatic shafts for cores of 76.2 mm (3”) (standard), and 152.4 mm (6”) (optional) |

Borderless printing flexible media | Yes |

Media

Media types | Handles a wide variety of flexible substrates. Check with your local Agfa representative for a detailed list. |

|---|

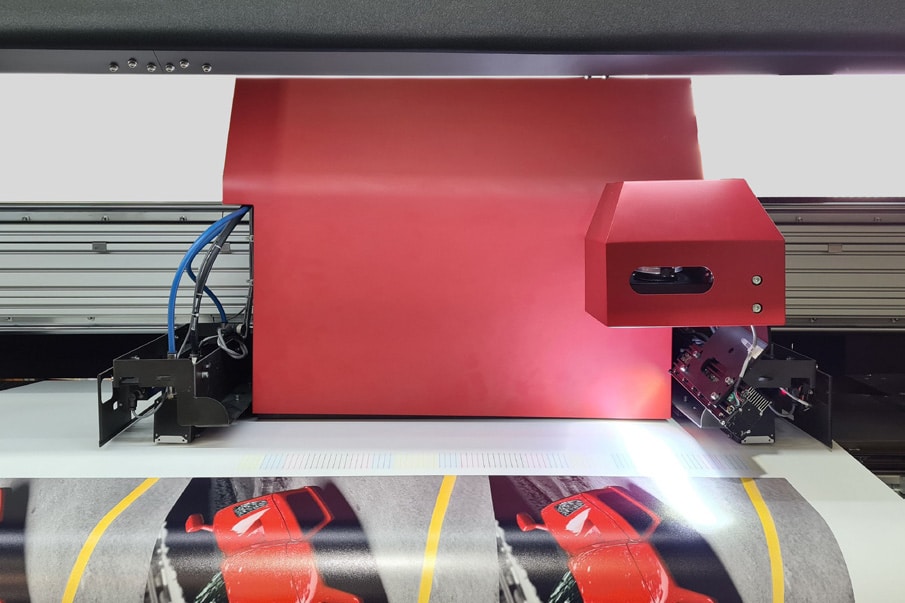

Print heads & inks

Print heads | Piezo drop-on-demand inkjet technology 18 print heads with 7 pl printheads | Piezo drop-on-demand inkjet technology24 print heads with 7 pl printheads |

|---|---|---|

Ink | Anuvia 1480 RTR CMYK + optional lights (cmk), white and clear fluid | Anuvia 1480 RTR CMYK + optional lights (cmk), white and clear fluid |

Ink container volume | 5 liters | 5 liters |

Image & text quality

Image quality | Up to 1200 dpi true resolution |

|---|---|

Text quality | 3 pt |

Engine dimensions & weight

Printer dimensions (H x W x L) | 210 cm x 145 cm x 840 cm (82.68” x 57.1” x 330.71”) | 210 cm (with emergency light: 250 cm) x 180 cm x 840 cm (82.68” x 70.87” x 330.71”) |

|---|---|---|

Printer weight

(Unit comes in one crate) | Crated: 7,000 kg (15,432 lb) Uncrated: 5,500 kg (12,125 lb) | Crated: 8,000 kg (17,640 lb) Uncrated: 6,500 kg (14,330 lb) |

Room conditions

Temperature | 20-30°C (68-86°F) |

|---|---|

Relative humidity | Standard range: 30% – 80% (non-condensing) Optinal range: 50% – 80% (non-condensing) |

System integration RIP/workflow software

Asanti, StoreFront, PrintSphere, third-party RIPs |