Jeti Tauro H3300

Extremely productive hybrid wide-format UV LED inkjet printer range

Driven by relentless determination, the rugged Tauro is ready to take on any print job, ensuring you hit the bull’s eye 24/7. With its versatile configurations, this sturdy beast unleashes fierce performance, allowing you to experience rugged reliability and charge ahead with primal force.

- Hybrid

- Up to 1,280 m²/h – 13,778 ft²/h

- Up to 330 cm – 130 in

- Automatable

- Speed & colors upgradable CCMMYYKK | CMYKck | CCMYKKck | CMYKKcmk | Optional W/P/V

Why the Tauro is the right beast for you

Our fastest hybrid press offers 24/7 productivity and award-winning quality on a wide range of rigid and flexible materials with the lowest ink consumption. With its many automation options, it’s the perfect solution for larger print service providers.

- Versatile printer: tackles nearly all sign & display jobs, as well as packaging

- Heavy-duty build for 24/7 printing with impressive productivity

- Award-winning quality with excellent solid colors and a neutral gray balance

- Varnish for extra brilliance and impact

- Several automation options to up your production efficiency when printing long runs or multiple boards

- Great autonomy gives you peace of mind

- UV LED technology brings economic and ecological benefits

- Thin Ink Layer technology for lowest ink consumption

- Powered by smart Asanti workflow software

Unleash fierce performance. Experience rugged reliability. Charge ahead.

A myriad of media and print applications

The Tauro H3300 range is suited for banners, posters, signage, exhibit graphics, POP, mockups, packaging, backlit, front-lit, self-adhesives, etc. The printers can also be used for niche applications such as wood, art reproductions, glass, or interior decoration.

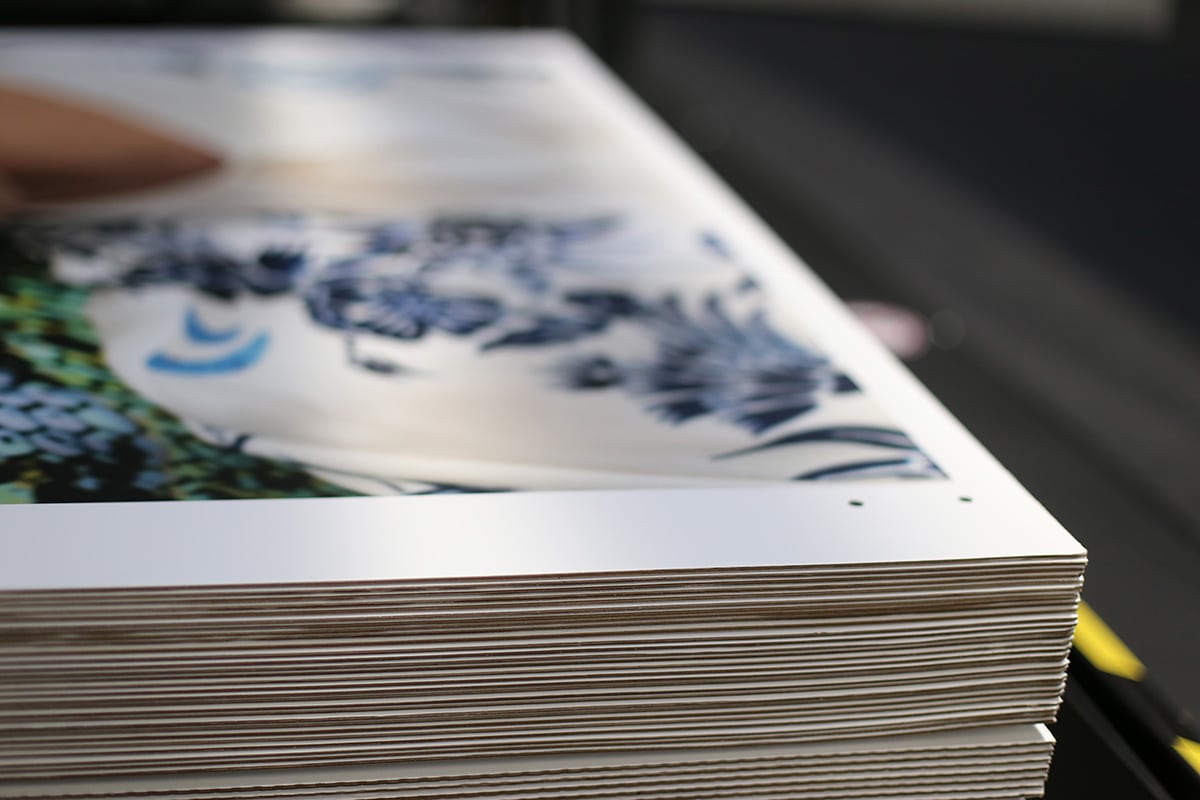

Great for cardboard

Thanks to its super-sturdy build, its dynamic extended vacuum zone, advanced automatic loader and smart media guides, the Tauro family is also especially suited for cardboard printing.

Luxury embellishments

The Tauro H3300 HS, UHS and XUHS let you add a layer of varnish to your displays to make them shine. The varnish can be applied to the entire surface (flood) or to selected areas (spot).

Brown packaging boxes

Transition sampling and low- to mid-range packaging print runs to your Tauro. It’s perfect for printing brown boxes typically used for secondary or tertiary packaging in e-commerce in one pass.

Take your productivity to the MAX

The Tauro family delivers high-speed performance, and its multiple automation options ensure this beast is not limited by human capabilities. Automation is essential for maximizing productivity, ensuring consistency and achieving peak efficiency, ultimately providing the best total cost of ownership, and helping you manage the challenges of rising expenses.

Whether you operate a dedicated rigid and sheet production facility, handle only roll media, or seek to combine both types of substrates, the MAX range of automation solutions provides the perfect solution to optimize your operations.

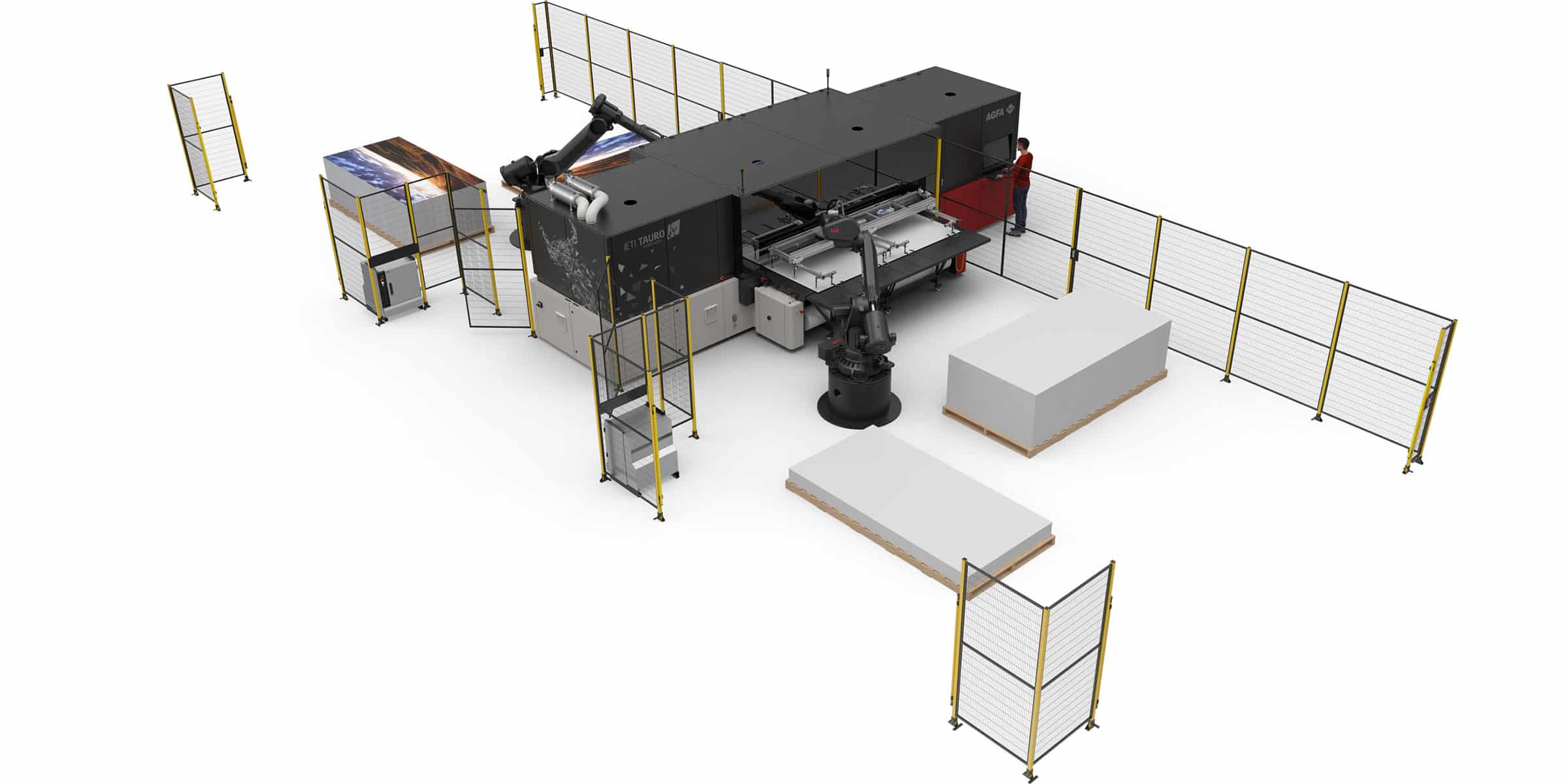

Automation for boards and sheets: MAX BOTS

Maximize your throughput and versatility with robotic media handling! Whereas a single robot can be used either for feeding in for stacking media, a dual-robot setup will completely automate your printing operations. The robots can handle up to 150 load cycles per hour. They can be used with a wide scope of substrates including sheets, corrugated and rigid boards up to 2.1 m x 3.3 m.

Ideal for

Print service providers who handle a variety of materials and are looking to maximize productivity and seamlessly switch between rigid substrates and roll media.

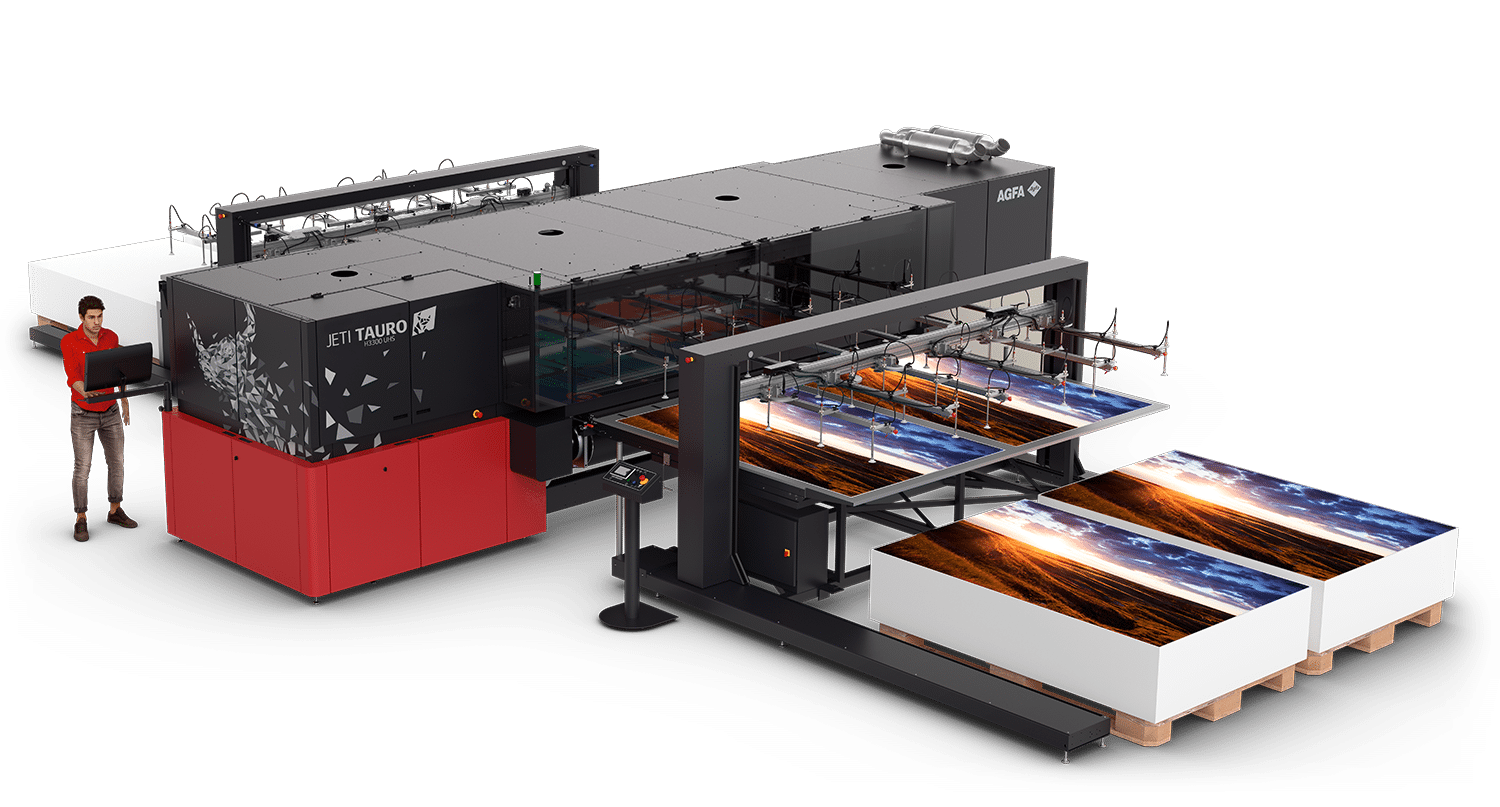

MAX Feeder & Stacker

Dedicated feeder & stacker solution for rigid & sheet. Media up to 2.65 x 3.30 m. While one board (set) is being printed, the next one is being prepared.

Ideal for

Fully automated printing of larger runs with single or multiple stacks. Automatically printing multiple boards will increase your productivity.

Models

MAX Pro: a cost-efficient step-in design, achieving productivity up to 80 load cycles per hour

➔ Ideal in combination with the Jeti Tauro S & HS models

MAX Elite: the full option version featuring a second gantry, boosting productivity to 120 load cycles per hour

➔ Supports faster press configurations like the Jeti Tauro XUHS

Printer models

Tauro H3300 S

- Up to 450 m²/h

- 4 rows of print heads

- Field upgradable to a 6-row CMYKcK

- Avaliable options: white, primer

Tauro H3300 HS

- Up to 680 m²/h

- 6 rows of print heads

- 4 or 6 colors

- 2x CMYK: focus on productivity

- CMYKcK: enhanced image quality

- CCMYKKcK: superior image quality thanks to extra redundancy in dark colors

- Avaliable options: white, primer, varnish

Tauro H3300 UHS

- Up to 905 m²/h

- 8 rows of print heads

- 4, 6 or 7 colors

- 2x CMYK: focus on productivity

- CCMYKKcK: superior image quality thanks to extra redundancy in dark colors

- CMYKKcmk: enhanced image quality with optional light & mid-tone colors

- Advanced automation to keep up with fast printing modes

- Extended vacuum for cardboard printing

- Avaliable options: white, primer, varnish

Tauro H3300 XUHS

- Up to 1 280 m²/h

- 12 rows of print heads

- 4 or 7 colors

- CCMMYYKK: focus on productivity

- CMYKKcmk: enhanced image quality with optional light & mid-tone colors

- Advanced automation to keep up with fast printing modes

- Extended vacuum for cardboard printing

- Avaliable options: white, primer, varnish

Loading/unloading configurations

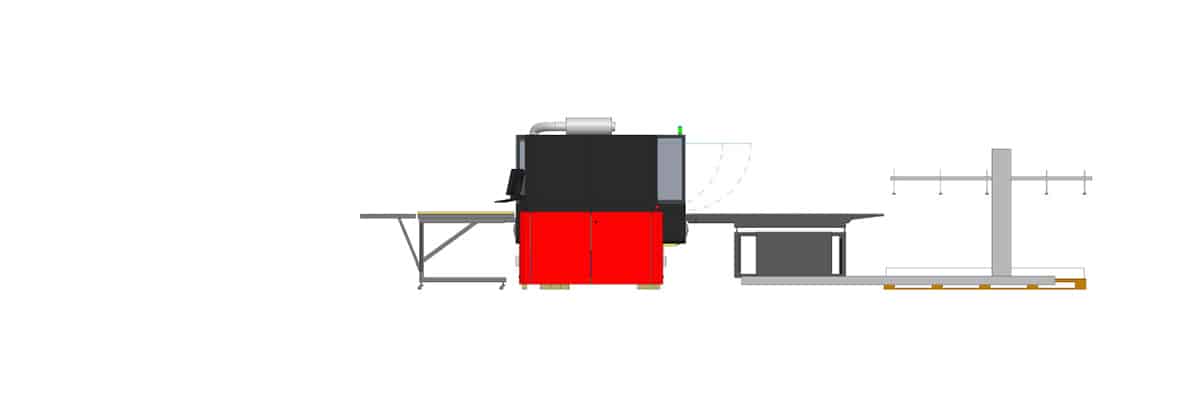

Manual loading and unloading

- Input and output tables for single or multiple board printing

- Perfect for short runs or handling different types of media

- Optional 3-point alignment bar on the input tables allows for easy and accurate media alignment. This supports more precise double-sided printing of thin media or skewed media, as well as correct cutting, e.g. of cardboard for packaging.

- Embedded continuous print solution enhances productivity in rigid mode as it narrows down the gap between two consecutive boards

Can be converted into a semi-automation, a ¾ automation, and combined with a light or a master roll-to-roll configuration

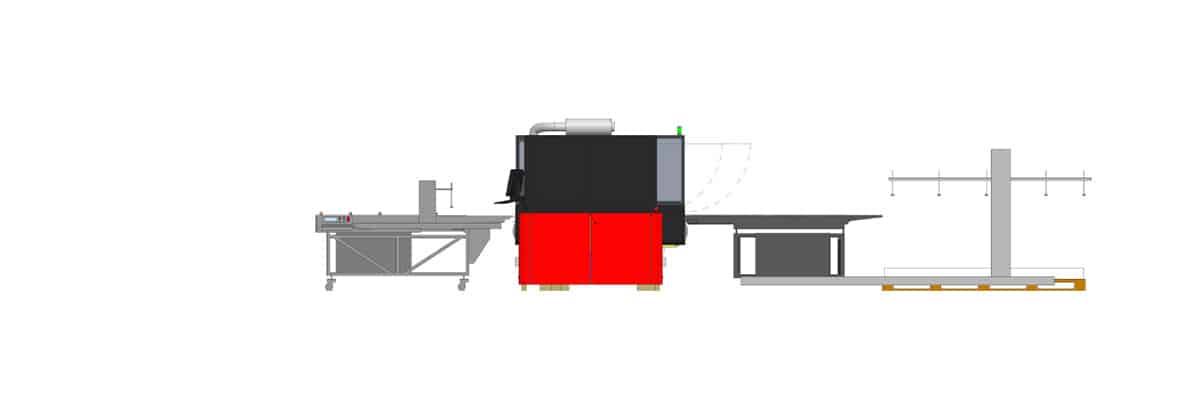

Semi-automation

- Manual loading table, automated unloader

- Optional 3-point alignment bar on the input tables allows for easy and accurate media alignment. This supports more precise double-sided printing of thin media or skewed media, as well as correct cutting.

¾ automation with automatic board feeder (ABF)

- Manual loading with automatic alignment and transport to the printer

- Ideal for shorter runs or fast and efficient changeover between different media sizes or types. The ABF takes over part of the operator’s tasks, including accurate alignment.

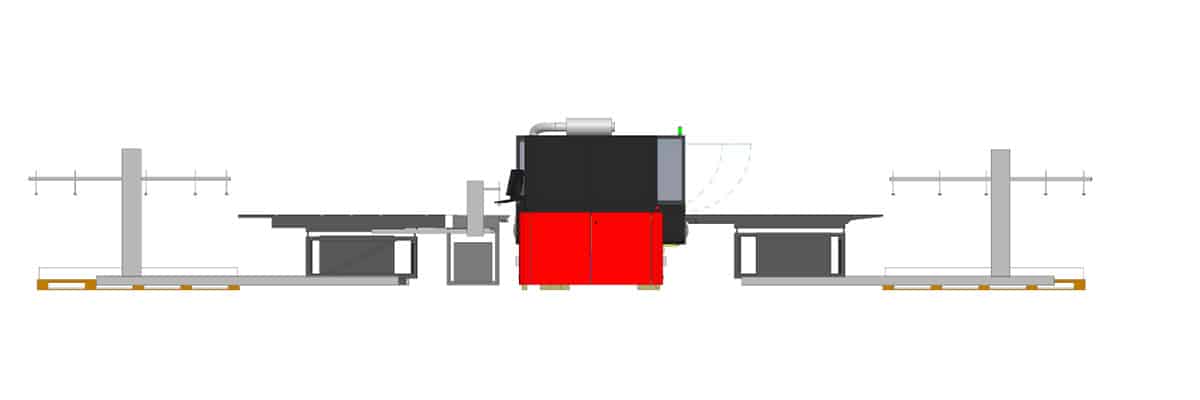

Full automation

- Automatic loading and unloading

- For larger runs or runs with multiple board stacks

- Multiple boards automatically, increasing your productivity

- While one board set is being printed, the next one is being prepared

- UHS models have an optional second gantry for the fastest printing modes

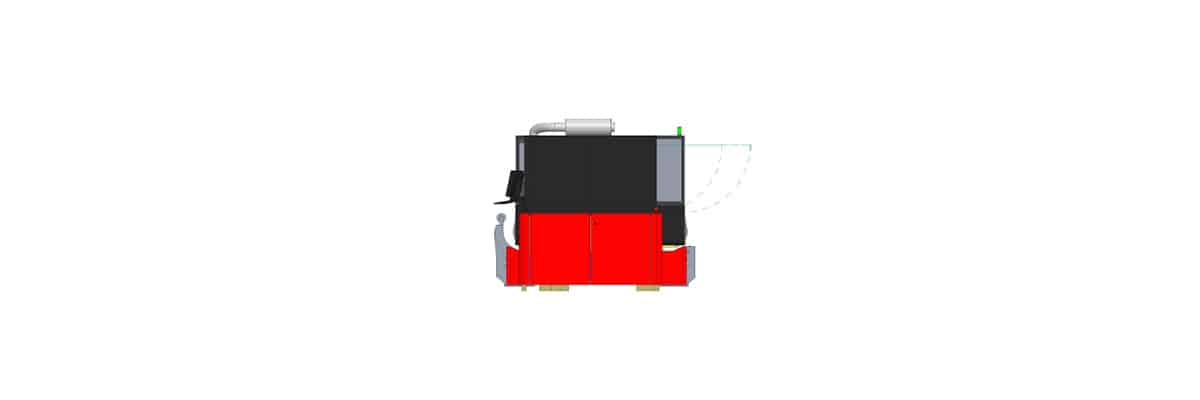

Light roll-to-roll

- For occasional, short single roll-to-roll or work

- Fast switchover between roll-to-roll and sheet mode

- Maximum weight of 200 kg per roll and a diameter of 250 mm

Can be combined with manual (un)loading tables and the automatic board feeder

Flex roll-to-roll

- Remains docked, thus allowing swift switching between rigid and flexible media

- For roll-to-roll or roll-to-floor printing

- Single- or dual-roll printing

- Compact footprint; ergonomic & user-friendly

- Handling rolls up to 450 kg with a diameter of 400 mm

- All onboard concept: no roll switching needed between single- or dual-roll mode.

Can be combined with manual (un)loading tables.

Flex roll-to-roll system: Maximize production efficiency

Benefit from increased flexibility with the Flex RTR system. As it doesn’t need undocking when transitioning from rolls to boards or sheets – the input and output tables simply attach over the roll system – printer uptime is increased.

The Flex RTR can handle both single- and dual-roll printing and features an integrated camera for accurate double-sided printing.

The module has a compact footprint and is user-friendly: a single operator can effortlessly load media with the simple push of a button.

Master roll-to-roll

- Designed to handle very large and heavy rolls

- For roll-to-roll or roll-to-floor printing

- Single- or dual-roll printing

- Handling rolls up to 700 kg with a diameter of 600 mm

- Dockable rolls for easy switching between rolls and rigids.

Can be combined with manual (un)loading tables and the automatic board feeder

Industry-leading print quality

Whatever you are creating, the Tauro printers, powered by Agfa’s signature UV LED-curable inks, deliver a wide color gamut and high color vibrancy. Asanti’s color management module allows for accurate mapping of spot colors and neutral gray printing, while the robustness of the printers and their precise media transport, combined with specific jetting algorithms and masking technology, results in excellent solid color reproduction on a wide variety of media. The 6-color models include light black (CMYKLcLk), guaranteeing a perfectly neutral gray balance.

Your customers will enjoy a print quality resembling offset printing, with fine details and smoothness throughout. The 7-pl droplets produce stunning images at 635 x 1200 dpi with a fine rendering of shadow and highlight details and razor-sharp texts in as small as 4-point type both in positive and negative text. The printers also excel in smooth ramp-ups over the tonal range, with outstanding skin tone rendering.

A whole new level of brilliance

HDR screenings, available as an option in our Asanti workflow, extend the color gamut and provide better Pantone reproduction without sacrificing speed. This will enable you to achieve your customers’ brand colors better without having to slow down your press.

Agfa-made inks: the perfect match

Specially formulated to print on rigid or flexible media, Agfa’s GREENGUARD Gold certified Anuvia UV LED inks broaden the scope of possible applications. This is what you can expect:

- Vibrant colors, impressive results

- The lowest ink consumption out there

- Excellent adhesion and durability

- Advanced white printing and ink management

- Primer option

- Compliant to industry norms

Software solutions

Asanti ——Dedicated Sign & Display workflow software

The Tauro H3300 engines are driven by Agfa’s award-winning wide-format workflow software Asanti, which controls the entire printing process from prepress to production and finishing. As such, it simplifies, optimizes and automates as many steps as possible, offering you a high-performance solution for increased productivity.

Simplify & automate

Including the latest Adobe PDF Print Engine, Asanti takes care of preflighting and job conversion to guarantee smooth, error-free job handling and consistent print quality. In addition, Asanti streamlines your print operations through automatic job layout and positioning, and automatic true-shape-nesting. The automatic collection of images allows you to gather all artwork for a specific press and specific media, and to optimally nest it on the print sheet or roll, taking copy count and bleed into account.

Asanti guarantees consistent color reproduction through the creation and use of color profiles. To do so, it deploys the patented Calibrated Print Mode (CPM) feature, which uses easy-to-set-up production templates that contain all parameters for a particular substrate and enable automatic job creation. It will only take you 15 minutes to calibrate and profile media, and then you can enjoy hassle-free printing with optimal and consistent quality!

The Asanti Production Dashboard is a browser-based reporting tool that allows you to inspect the status, ink and media consumption, and printing time of jobs.

Asanti can also drive non-Agfa printers and a wide range of cutting tables, and it offers JDF/JMF-based integration with many MIS solutions. To link a non-Agfa RIP/workflow with the Tauro printers, we developed TauroConnect, which captures data from the workflow in place and takes care of screening, output quality, and printing parameters.

Technical data

Tauro H3300

Models | Tauro H3300 S | Tauro H3300 HS | Tauro H3300 UHS | Tauro H3300 XUHS |

|---|---|---|---|---|

Tauro H3300 S – 6 colors (24 heads)

Options:

The Tauro H3300 S is upgradable to a Tauro H3300 HS – 6 color (36 heads) configuration | Tauro H3300 HS – 6 colors (36 heads) Tauro H3300 HS – 6 colors+ (48 heads) Tauro H3300 HS – 2 x 4 colors (48 heads)

Options:

| Tauro H3300 UHS – 6 colors+ (64 heads) Tauro H3300 UHS – 7 colors (64 heads) Tauro H3300 UHS – 2 x 4 colors (64 heads)

Options:

| Tauro H3300 XUHS – 7 colors (96 heads) Tauro H3300 XUHS – 2 x 4 colors (96 heads)

Options:

| |

Productivity | Up to 450 m²/h (4,844 ft²/h) | Up to 680 m²/h (7,319 ft²/h) | Up to 905 m²/h (9,741 ft²/h) | Up to 1,280m²/h (13,778 ft²/h) |

Media & printing specifications – Sheets & boards

Maximum width | Base engine: 3.34 m (131.49” = 10.95 ft) Feeder, stacker and ABF: 3.30 m (130” = 10.8 ft) |

|---|---|

Maximum length | Base engine: 4.0 m (157.48” = 13.12 ft) Feeder: boards & flexible sheets: 2.65 m (104.33” = 8.69 ft) Stacker: boards & flexible sheets: 2.65 m (104.33” = 8.69 ft) ABF: combined with input & output tables: 4.0 m (157.48” = 13.12 ft) / / combined with stacker: 2.65m (104.33” = 8.69 ft) for boards and flexible sheets |

Minimum size | Base engine: A2: 42.0 cm x 59.4 cm (16.5” x 23.4 in) Feeder, stacker and ABF: A1: 59.4 cm x 84.1 cm (23.4” x 33.1”) (in portrait) |

Thickness | Base engine: min. 0.2 mm (8 mil) – max. 5 cm (2”) media-dependent Feeder, stacker and ABF: min. 0.2 mm (8 mil) – max. 2 cm (0.8”), media-dependent |

Weight | Base engine: 10 kg/m² (2 lb/ft2) evenly distributed – Sheets: from 200 g/m² (0.04 lb/ft2) Feeder, stacker and ABF: 10 kg/m² (2 lb/ft2) with max. 25 kg (55.1 lb) per load cycle – Sheets: from 200 g/m² (0.04 lb/ft2) |

Borderless printing | Yes, with protection paper or tape on the belt |

Media & printing specifications – Roll-to-Roll

Maximum width | Light roll-to-roll* Single roll: 3.2 m (126” = 10.5 ft) Flex roll-to-roll Single roll: 3.3 m (130” = 10.83 ft) / Dual roll: 1.6 m (63” = 5.25 ft) Master roll-to-roll Single roll: 3.3 m (130” = 10.83 ft) / Dual roll: 1.6 m (63” = 5.25 ft) |

|---|---|

Minimum width | Light roll-to-roll* Single roll: 61 cm (24” = 2 ft) Flex roll-to-roll Single & dual roll: 61 cm (24” = 2 ft) Master roll-to-roll Single & dual roll: 61 cm (24” = 2 ft) |

Maximum length | Full roll length (depends on total roll thickness, diameter and weight) |

Thickness | Light roll-to-roll* Single roll: max. 2 mm (0.08”) (80 mil) – min. 0.2 mm (0.008 in) (8 mil) Flex roll-to-roll Single & dual roll: max: 2 mm (0.08”) (80 mil) – min: 0.2 mm (0.008 in) (8 mil) Master roll-to-roll Single & dual roll: max: 2 mm (0.08””) (80 mil) – min: 0.2 mm (0.008 in) (8 mil) |

Maximum weight | Light roll-to-roll* Single roll: up to 200 kg (440.92 lb) per roll in full width*, mounted at the center of the shaftFlex roll-to-roll Single roll: up to 450 kg (992.08 lb) in full width*, mounted at the center of the shaft Dual roll: up to 450 kg (992.08 lb) per roll* (each roll centered on its shaft) Master roll-to-roll Single roll: up to 700 kg (1,543.24 lb) in full width*, mounted at the center of the shaft Dual roll: up to 700 kg (1,543.24 lb) per roll* (each roll centered on its shaft) * The maximum weight depends on the roll width. |

Maximum roll outside diameter | Light roll-to-roll* 250 mm (9.8”) Flex roll-to-roll Single & dual roll: 400 mm (15.7”) Master roll-to-roll Single & dual roll: 600 mm (23.6”) |

Roll mounting | Pneumatic shafts for cores of 76.2 mm (3”) (standard), and 152.4 mm (6”) (optional) |

Borderless printing flexible media | Yes, with tape on the belt |

Media

Media types | Rigid as well as flexible media. Check with your local Agfa representative for a detailed list. |

|---|

Print heads & inks

Print heads | Ricoh MH5420 | Ricoh MH5420 | Ricoh MH5420 | Ricoh MH5420 |

|---|---|---|---|---|

Ink | Anuvia CMYKck + white and primer | Anuvia CMYKck + white, primer and varnish | Anuvia CMYKcmk + white, primer and varnish | Anuvia CMYKcmk + white, primer and varnish |

Image & text quality

Image quality | Resolution up to 1200 dpi |

|---|---|

Text quality | 4pt |

Room conditions

Temperature | 16-25°C (61-77°F) |

|---|---|

Relative humidity | 40-60% |

System integration RIP/workflow software

Asanti, StoreFront, PrintSphere, third-party RIPs |