On July 4, 2025, the Digital Printing × Flexographic Printing Technology [Dual Engine Innovation] Roadshow, jointly organized by Beijing Keyin Media, GIP, Shanghai Spande and AP LABEL, was successfully held at the AP LABEL Printing Factory.

The event on site attracted over 150 outstanding representatives from label printing enterprises and industry experts to participate in the activity. This event not only enabled everyone to deeply understand how AP LABEL combines digital and flexographic printing in practical application to production, but also saw GIP release its latest digital and flexographic printing integration solution - Falcon, and successfully signed contracts with two important clients.

Factory Tour: Immersive Technology Experience

At the beginning of the event, the customers first visited the two combined hybrid production lines of the AP LABEL Printing Factory. One of them was the Label Modular 330 HD, which was installed and put into operation last December. The other one is the brand-new hybrid solution - Falcon, which was officially launched today.

During the visit, the technicians from GIP demonstrated the outstanding performance and unique features of the two different hybrid solutions through on-site explanations and practical production demonstrations. The high-precision 1200dpi printhead accurately sprayed ink on various substrates, creating detailed and clear patterns and text with natural color transitions and excellent quality details. Even under high-speed operation, the equipment remained stable and efficiently completed the printing tasks, earning continuous applause from the audience.

Roadshow: Unveiling the Mystery of the New Product

Zhong Xiaochun, the executive director of AP LABEL, delivered a welcome speech. He first warmly welcomed the leaders, label industry experts, and colleagues from the label industry who attended this event. At the same time, he expressed his most sincere gratitude to all the friends from various sectors who have long supported and helped AP LABEL. In his speech, he highly praised the GIP · Spande Label Modular hybrid printer. He stated that this event is not only a window for AP LABEL to showcase its technical achievements, but also a bridge for in-depth dialogue with industry colleagues.

Huang Xuebin, the CEO of General Inkjet Printing Technology Co., Ltd., first extended a warm welcome to all the guests and label professionals attending this event. He stated that GIP has always focused on the pain points of the label industry and has launched digital printing printer that balances quality, efficiency and cost. The new product that will be released today is a significant achievement that breaks free from the shackles of traditional processes and will provide more options for the digital upgrade of the label printing industry.

Ye Keqin, the CEO of Shanghai Spande, first extended a warm welcome to all the guests who had come from afar and expressed gratitude to AP LABEL for opening its factory for the first time and providing an immersive visiting experience for industry colleagues. He stated that Spande and AP LABEL have been working together for seven years. With the successful launch of new products, he hopes to bring another "powerful fighter" to AP LABEL. In the future, Spande will strengthen communication and exchanges with colleagues in the label industry and introduce more targeted equipment solutions.

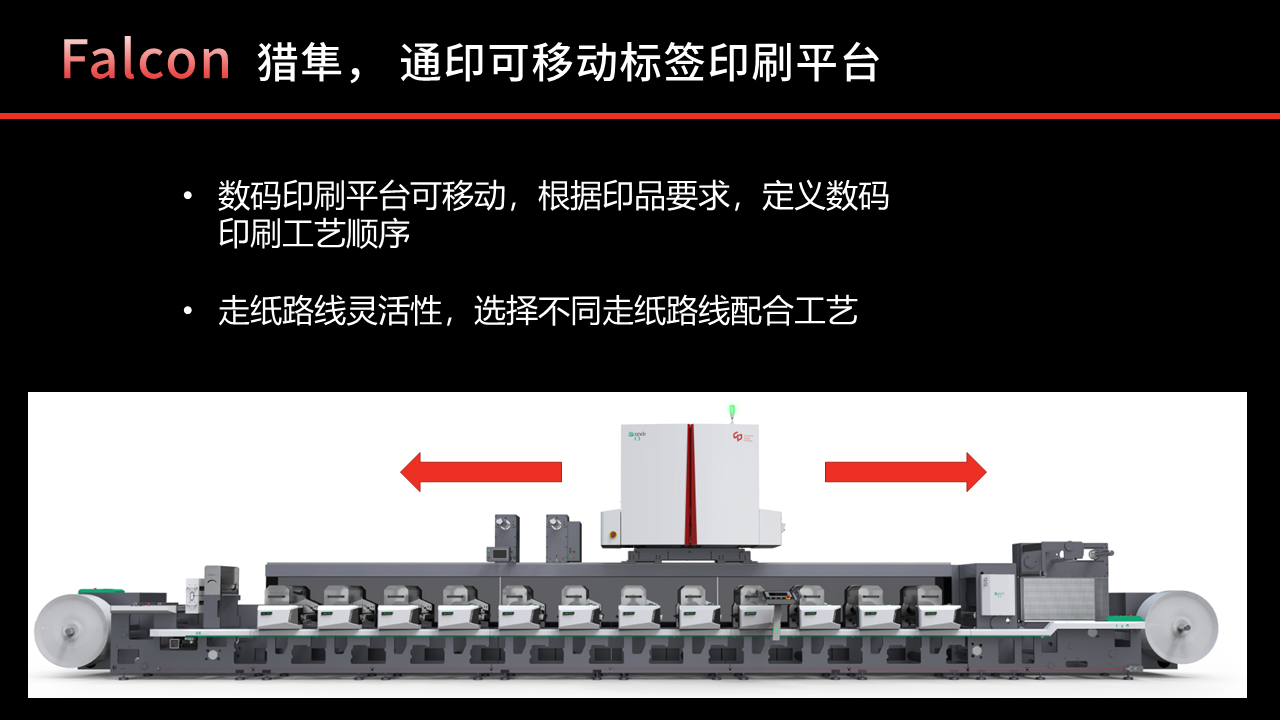

Ge Yujun, the vice manager of GIP, unveiled the new product of the strong alliance between GIP and Shanghai Spande - the Falcon, movable label printing platform. In his speech, he comprehensively introduced the core competitive advantages of the new product from perspectives such as process technology, application fields, and color management.

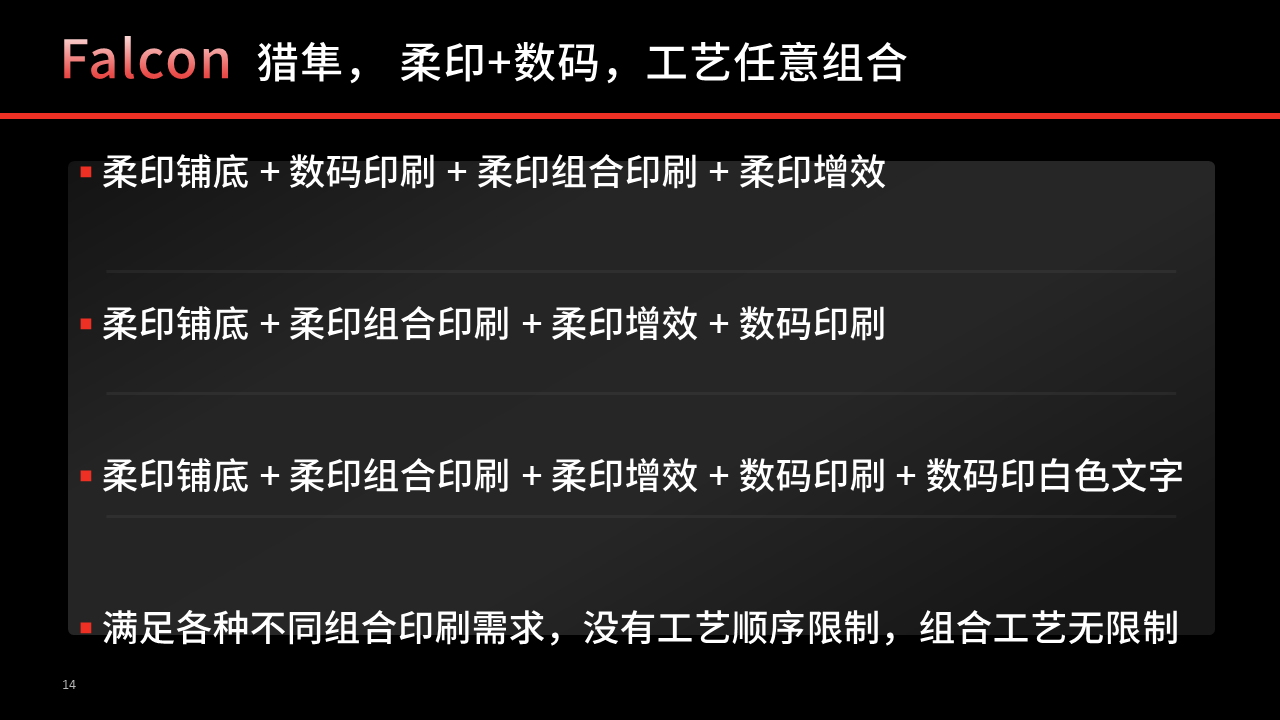

Highly flexible process combination

Break the limitations of traditional process, support any combination of flexographic printing and digital printing, and meet diverse printing demands. The digital printing platform can be moved according to the requirements of the printed products, and the digital printing process can be customized; the flexibility of the paper path can meet the requirements of different printing processes.

High efficiency and low cost

The digital printing platform can be easily installed onto existing flexo production lines. Its maximum running speed can reach 81m/min, significantly enhancing the overall production efficiency of the equipment and shortening the production cycle. Equipped with an ink circulation system, it can more precisely control the use of ink. Combined with the AGFA Apogee ink-saving function and Asanti GCR technology, it optimizes color management and can precisely control ink droplet distribution, potentially saving up to 20% to 30% of ink.

Excellent printing quality

Equipped with Kyocera 1200×1200dpi high-resolution printheads, it supports CMYK + OGVW 8-color printing, achieving a wider color gamut and enhancing both saturation and vividness. The unique technology eliminates the white lines caused by printhead blockage through software algorithms and high-precision vision systems, ensuring stable printing quality.

Wide color gamut ink

High color concentration, wide color gamut, and high coverage of ink color inks enable more accurate reproduction of image effects. Spot color matching can be achieved within 10 minutes, with zero color difference when reorder, meeting the high-end customization needs of customers.

渡邉勇人,the sales director of the Kyocera inkjet division, also attended the roadshow. He witnessed this significant moment and congratulated the company on the launch of this new product.

He stated that the application of the latest 1200dpi UV printhead by GIP has been extremely perfect. The new product Falcon from GIP operates very quietly, which fully demonstrates the high-level matching and excellent stability of each component of the equipment. To his surprise, Falcon through its innovative movable and flexible design has broken through the application limitations of traditional digital flexographic equipment. He hopes that all the customers attending this event will be able to learn about the latest technologies in label application through this event.

Signing Ceremony: Jointly Commence a New Journey of Cooperation

Under the joint witness of the attending guests, GIP and Shanghai Spande respectively held a grand on-site signing ceremony with Wenzhou Haoge and Shanghai Hengze. These two clients have significant influence in their respective fields. This signing is a high-level recognition of the quality of GIP's digital inkjet technology and Shanghai Spande's flexographic technology.

Signed contract with Wenzhou Haoge Anti-counterfeiting Technology Co., Ltd.

Signed contract with Shanghai Hengze Printing Co., Ltd.