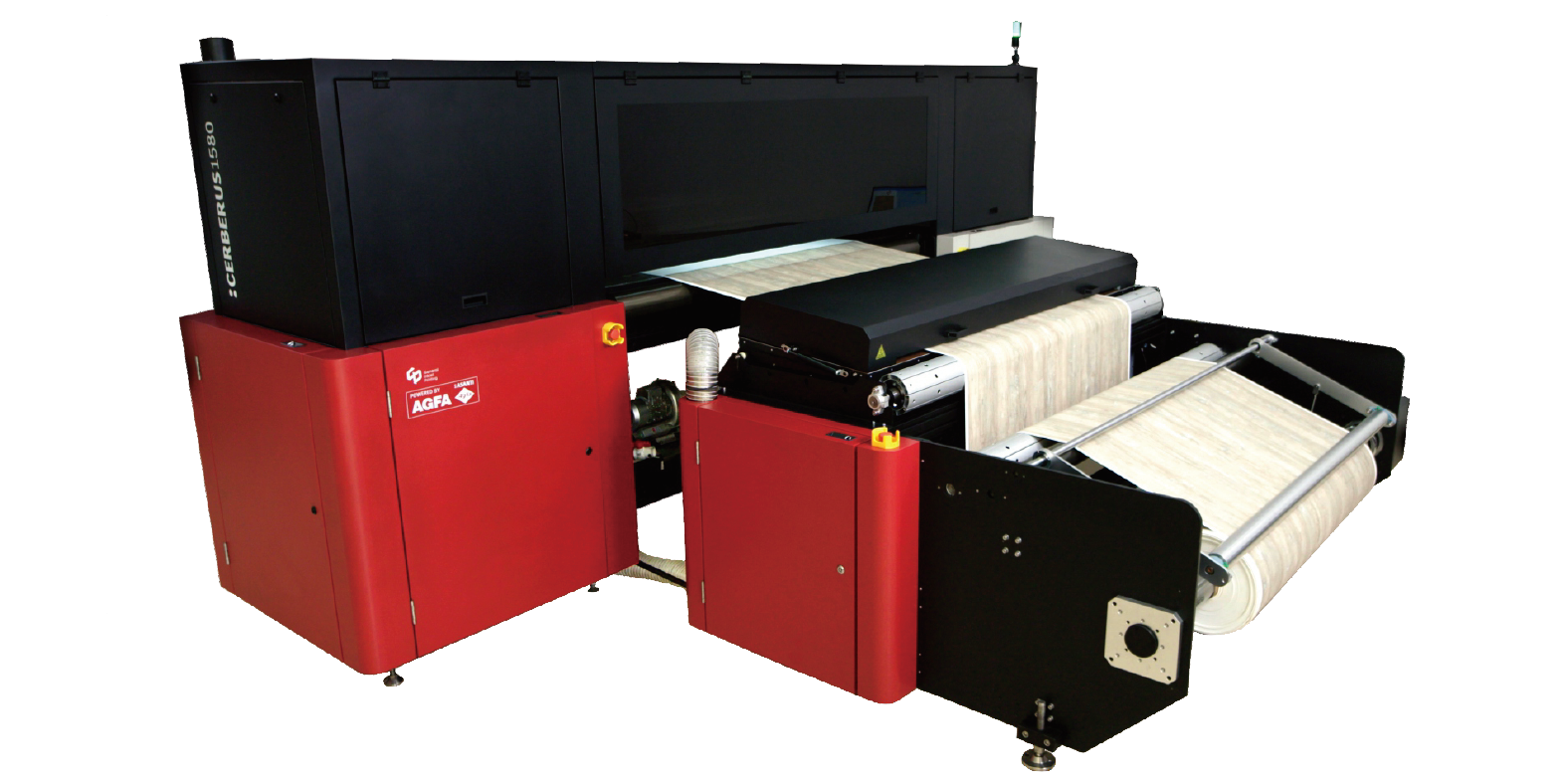

Cerberus 1580

Integrated digital printing solution for decor papers

The Cerberus is a multi-pass, water-based inkjet system for printing on decor paper used for interior decoration, such as laminate floors and furniture.It can print on rolls with a width of up to 158 cm and a weight of up to 600 kg

Comprehensive solutions include high-quality inks and paper primers with a wide color gamut, thin ink layer and low ink consumption. Efficient production process software with integrated color management and quality control provides a relatively low operational cost for the digital work of short-run lengths. Provide designers a broad space of imagination to explore new business opportunities and business modes.

Key benefits

- Smart Graphic User Interface (GUI), efficient and simple to operate.

- Infrared drying and color fixing system guarantees that the water content of papers meets industrial requirements.

- Automatic print head maintenance system prevents print head clogging, ensuring readiness to work at any time.

- Large-Roll feeding system with a total winding and unwinding capacity up to 600 kg, eliminating the need to rewind into smaller rolls before printing. Rewinded roll can be trimmed to required lengths at any time.

- Industrial-grade print heads bring stable and reliable colors and sharp images with perfect printing quality.

Watch the movies

Features

Color Management Workflow Software

With 30 years of color management experience, the workflow software is equipped with the latest APPE processing core with icon-based process flow interface, powerful functions and simply to use.

Color separated files are uploaded to the Agfa Cerberus Asanti for a complete interpretation of spot colors and overprinting, then print with CRYKLk inks to achieve the best color reproduction.

Agfa Cerberus DL Dedicated Water-based Inks for Decor Papers

Agfa’s water-based inks are formulated with high-performance pigment and dispersion agent and can achieve a wide color gamut with extremely low ink consumption.

With exclusive ink formulas and extraordinary pigment dispersion quality, Agfa’s water-based inks boast one of the highest shelf lives in the industry. Depending on the ink series, the shelf life of inks can up to 24 months under normal storage conditions.

No matter on digital decor papers or paper coated with Agfa primer, Agfa’s special purpose inks for decor papers are compatible with existing traditional impregnation and lamination processes.

Agfa Cerberus Primer

Agfa Cerberus inks printed on ordinary base papers coated with Agfa Cerberus primer is compatible with the existing impregnation and standard lamination production processes.

Upon drying and color fixing, ink droplets sharply hold on paper surface and perfectly integrated into board after impregnation and standard lamination production, exhibiting with sharp image colors.

A gravure press with appropriate flat tint cylinder can be used to coat primer evenly on base paper, convenience and efficiency.

One-stop Solution

The decor paper industry is in the mid-stream of the furniture/floor industrial chain ranging from base paper manufacturing to furniture/floor products. No mistake can be tolerated in any step of processing, from manufacturing to delivery of semi-finished and finished goods.

Instead of just assembling a machine, we provide a solution with extensively proven of mature and reliable. With many years of experience in the decor paper industry, we will continue developing new technologies and equipment and are committed to serving as your long-term partner.

Digital Printing Production

Over the years, gravure printing has been faced with numerous challenges: printing cylinders have a long production cycle with an exorbitant cost, and unpopular patterns are bound to lead to losses; non-repetitive large mosaic patterns, bright-colored patterns, geometric patterns and light-color patterns with large areas of gaps are difficult to realize with gravure printing; drop in single-order volumes increase inventory risks.

These challenges happen to be what :CERBERUS 1580 digital solution is poised to overcome: no platemaking, large format, non-repetitive patterns and zero inventory with on demand printing.

Decor Design

Decor design are the core competency of the decor paper industry.

In order to serve customers better, gain orders and success in competition, industry practitioners need to launch new product with high quality in a quick and low cost way.

:CERBERUS 1580 system includes advanced color management and high-quality inks appropriate for pattern development and customer proofing. Before making printing cylinders for large production, color matching and proofing can be printed with our system in small-quantity production. Printed papers are fully compatible with impregnation and lamination production. Once the large-quantity order is confirmed, convert to gravure printing is possible at any time.

Brochures

Technical Specs

Technical specifications |

|

| Printing technology | Industrial Piezoelectric print head |

Media |

|

| Media Types | Digital decor paper, coated base paper or base paper treated with primer |

| Maximum media weight | Total winding and unwinding capacity up to 600 kg, 3-inch paper core |

| Maximum media width | 1580mm |

| Ink | Agfa dedicated 5-color water-based inks for decor papers (CRYKLk) |

| Primer | Agfa Cerberus primer for decor papers |

Productivity (With a width of 1.58 meters as the standard) |

|

| Speed Mode | 52㎡/h |

| Normal Mode | 44㎡/h |

| Quality Mode | 33㎡/h |

Dimensions and weight |

|

| Dimensions (length*width*height) | 4308*4100*1990mm |

| Weight | 3500kg |

Working Environment |

|

| Temperature | 18~24℃ |

| Relative humidity | 35~55% relative humidity; no condensation |

Power |

|

| Printing unit | 9KW/220V |

| Winding and unwinding unit | 3KW/380V |

| Drying unit | 4.8KW |

| Total | 16.8KW |

Software |

|

| Agfa Asanti dedicated color management digital workflow software for decor papers | |

| AVA software (optional) | |

Technical specifications |

|

| Printing technology | Industrial Piezoelectric print head |

Media |

|

| Media Types | Digital decor paper, coated base paper or base paper treated with primer |

| Maximum media weight | Total winding and unwinding capacity up to 600 kg, 3-inch paper core |

| Maximum media width | 1580mm |

| Ink | Agfa dedicated 5-color water-based inks for decor papers (CRYKLk) |

| Primer | Agfa Cerberus primer for decor papers |

Productivity(With a width of 1.58 meters as the standard) |

|

| Speed Mode | 70㎡/h |

| Normal Mode | 58㎡/h |

| Quality Mode | 44㎡/h |

Dimensions and weight |

|

| Dimensions (length*width*height) | 4308*4100*1990mm |

| Weight | 3500kg |

Working Environment |

|

| Temperature | 18~24℃ |

| Relative humidity | 35~55% relative humidity; no condensation |

Power |

|

| Printing unit | 9KW/220V |

| Winding and unwinding unit | 3KW/380V |

| Drying unit | 4.8KW |

| Total | 16.8KW |

Software |

|

| Agfa Asanti dedicated color management digital workflow software for decor papers | |

| AVA software (optional) | |

Technical specifications |

|

| Printing technology | Industrial Piezoelectric print head |

Media |

|

| Media Types | Digital decor paper, coated base paper or base paper treated with primer |

| Maximum media weight | Total winding and unwinding capacity up to 600 kg, 3-inch paper core |

| Maximum media width | 1580mm |

| Ink | Agfa dedicated 5-color water-based inks for decor papers (CRYKLk) |

| Primer | Agfa Cerberus primer for decor papers |

Productivity(With a width of 1.58 meters as the standard) |

|

| Speed Mode | 88㎡/h |

| Normal Mode | 73㎡/h |

| Quality Mode | 56㎡/h |

Dimensions and weight |

|

| Dimensions (length*width*height) | 4308*4100*1990mm |

| Weight | 3500kg |

Working Environment |

|

| Temperature | 18~24℃ |

| Relative humidity | 35~55% relative humidity; no condensation |

Power |

|

| Printing unit | 9KW/220V |

| Winding and unwinding unit | 3KW/380V |

| Drying unit | 4.8KW |

| Total | 16.8KW |

Software |

|

| Agfa Asanti dedicated color management digital workflow software for decor papers | |

| AVA software (optional) | |