Oberon RTR3300

The Oberon RTR3300 is a dedicated 3.3 m high-end roll-to-roll machine that combines extreme productivity and quality with an extensive media scope and a unique ease of use.

The Oberon RTR3300 covers significant media diversity and a wide range of applications, including mesh and backlit prints. This enables you to execute all your customers’ creative wishes, while also inspiring them to explore new directions.

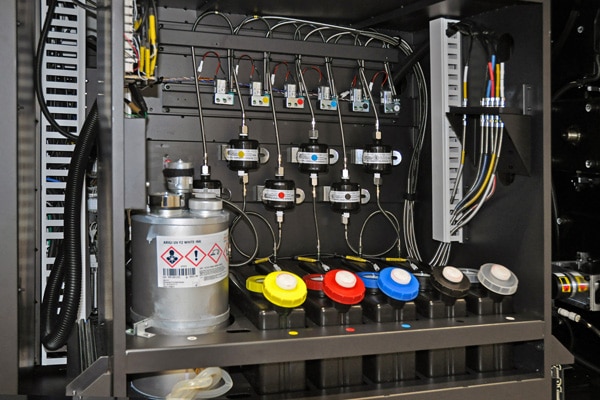

This sturdy and reliable workhorse comes in a four color plus white and a six color version, depending on user needs and preferences. The dual-roll option is capable of handling two rolls each up to 1.6 meters wide, doubling total output. A number of smart features optimize media use.

The UV LED inks on the Oberon RTR3300 were optimized for flexible media and excel in smooth solid color printing. They are fully compliant to industry norms for the protection of human health and the environment. Having obtained the highest category of GREENGUARD GOLD certification, they meet some of the world’s most rigorous chemical emissions standards.

The Oberon RTR3300 is driven by Agfa’s wide-format workflow software Asanti, which automates and simplifies the entire printing process from prepress through production to finishing.

Key benefits

- Extremely wide media and applications scope

- Dual-roll printing option for increased productivity

- Optimal media use thanks to a range of smart features

- Outstanding ease of use

- Dedicated & certified Agfa-developed inks for the best quality and the lowest ink consumption

Features

UV LED curing saves time and costs and benefits the environment

The Oberon RTR3300 is fitted with air-cooled UV LED lamps, providing a wide applications scope, high productivity (immediate start-up) and low energy consumption.

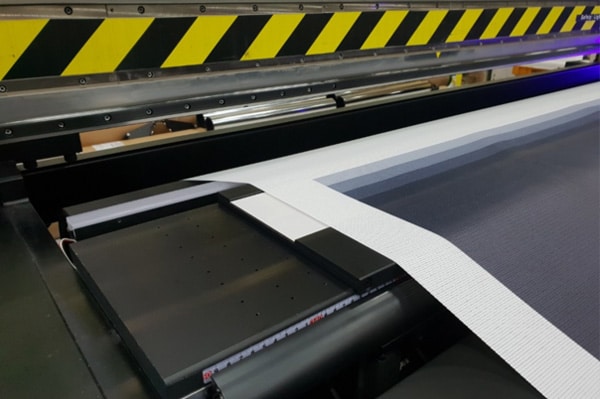

Water-cooled table expands media scope

In addition to its air-cooled LED curing lamps, the Oberon RTR3300 features a unique water-cooled table that keeps the printing zone at room temperature. This enables print service providers to smoothly process any kind of heat-sensitive roll material, including lower cost media.

Convenient mesh printing kit

The dedicated mesh printing functionality makes printing on mesh (with or without liner) more convenient than ever.

Free fall option reduces media waste

Pinch rollers at the front and back of the transport rollers enable free fall printing. This comes in handy to print on demand and results in optimal media use.

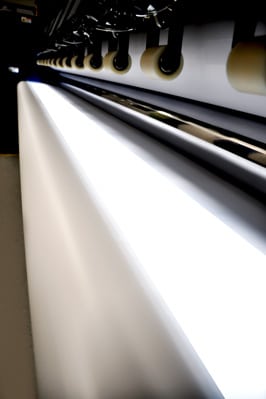

Convenient media loading

The Oberon RTR3300 was designed with a view to offering convenience, lean operations and peace of mind. Thanks to a unique media loading setup, a single operator can quickly load the media. Carbon shafts reduce the weight of the rolls.

Smart multi-queuing

The smart multi-queue functionality guarantees effortless job planning in view of the available materials.

Immediate quality inspection

A light box next to the printing area allows for on-the-spot quality inspection of backlit prints.

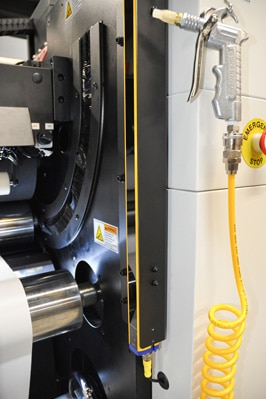

Double light curtain for uninterrupted printing

When an operator accidentally moves into the safety zone, a double light curtain sends the print shuttle back to its home base, while the print job keeps retained, ready to be continued as soon as possible. That way, no media or time go to waste.

Inks compliant to industry norms

The Oberon inks obtained the highest category of GREENGUARD GOLD certification, which means they meet some of the world’s most rigorous chemical emissions standards and can be used in sensitive indoor environments like schools or healthcare facilities.

Convenient mesh printing kit

Light box

Double light curtain

Ink supply

Technical Specs

| Oberon RTR3300 6-color | Oberon RTR3300 4-color + white | |

| Media & Printing Specifications | ||

| Print width (min-max) | Single roll: 61-330 cm (24”-130”)

Dual roll: 61-160 cm (24”-63”) |

|

| Borderless printing with mesh kit | Up to 330 cm media width (130”) | |

| Media thickness | Minimum: 0.2 mm (0.08”) / Maximum: 3.0 mm (0.12”) | |

| Maximum roll weight (including shaft) | 160 kg (180kg) over 3.3 m or 0.5 kg/cm media width | |

| Maximum roll diameter | 36 cm (14.17”) | |

| Productivity | ||

| Express mode | 150 m²/h (1615 ft²) | |

| Production mode | 85 m²/h (915 ft²) | |

| Standard mode | 43 m²/h (463 ft²) | |

| High-quality mode | 25 m²/h (269 ft²) | |

| Print heads & inks | ||

| Print heads | 6 Kyocera high-frequency print heads | 6 Kyocera high-frequency print heads |

| Inks | CMYKLcLm 1470 LED curable inks

GREENGUARD Gold certified |

CMYK + W Oberon 1470 LED curable inks (White is a factory-installed option.) GREENGUARD Gold certified |

| Image & text quality | ||

| Image quality | From express mode to high-quality mode | |

| Text quality | 4 point legible sans serif text, and 6 point in negative | |

| Engine dimensions & weight | ||

| Printer dimensions (W x H x D) | 6620 x 1960 x 2040 cm (21.7 ft x 6.5 ft x 6.7 ft) | |

| Printer weight | 4600 kg | |

| Floor space | 9.62 x 4.36 m (31.5 ft x 14.3 ft) | |

| Room conditions | ||

| Temperature | 18-26°C (61-77°F) | |

| Relative humidity | 35-70% | |

| Electricity & compressed air | ||

| Europe | 400 V 3-phase star connection with neutral wire (3 x 30A) 50/60 Hz | |

| USA | 230 V 3-phase delta connection without neutral wire (3 x 30A) 50/60 Hz | |

| System Integration RIP / Workflow software | ||

| Integrated solution with Asanti & PrintSphere; other RIPs on request Oberon RTR330 media/ink profiles standard on board with Asanti |

||

| Safety Approvals | ||

| CE, FCC, NRTL, ROHS | ||